With the continuous advancement of smart manufacturing and Industry 4.0, manufacturing enterprises have put forward higher requirements for production line flexibility, efficiency, and stability. Due to their fixed design concepts, traditional feeding systems often struggle when handling high-mix, small-batch, and multi-variety production. In contrast, flexible feeding systems, with their high adaptability and intelligent features, are becoming the "new standard" in industrial automation feeding.

I. What is a Flexible Feeding System?

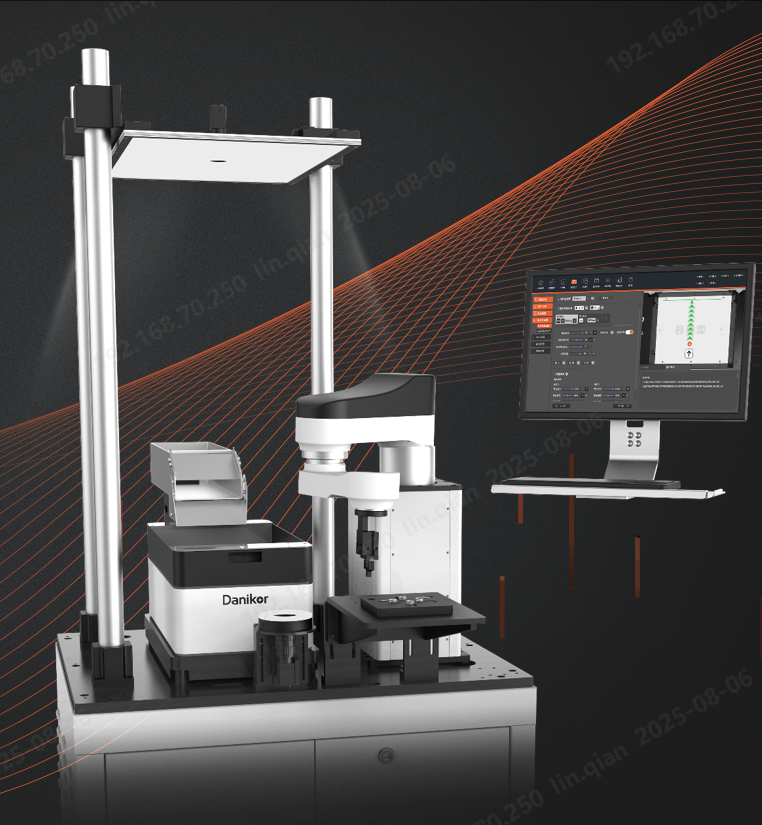

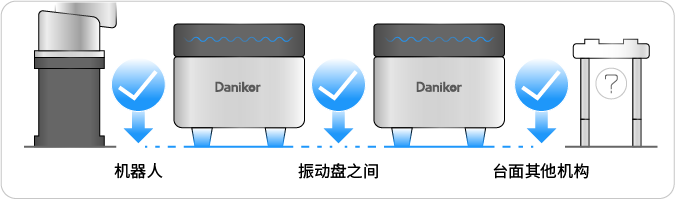

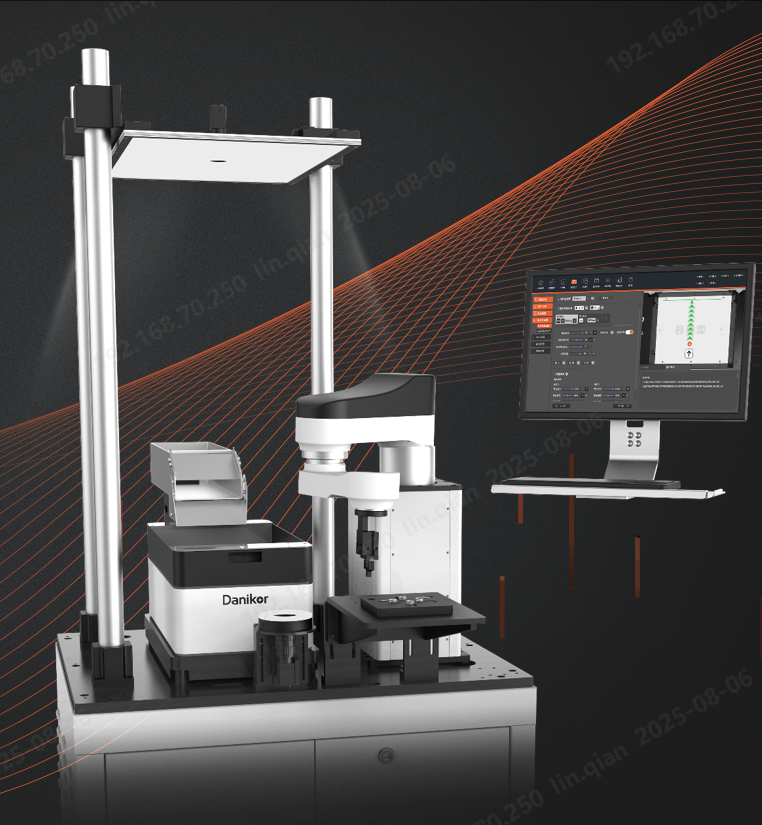

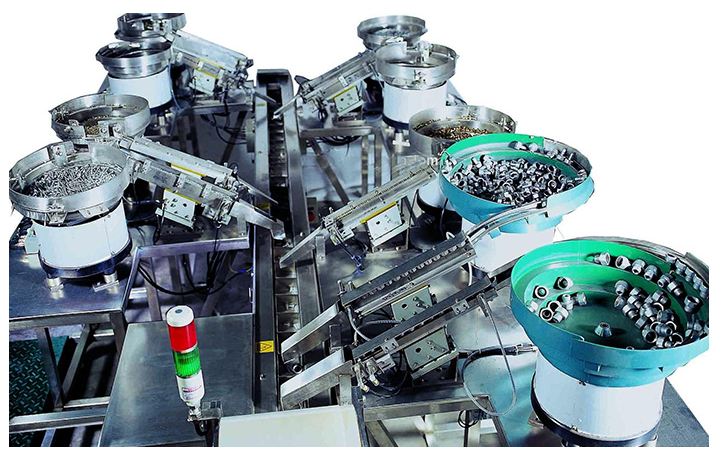

A flexible feeding system is an automated feeding solution that integrates vibration plates, vision positioning, and robotics. It can automatically identify, sort, and convey components of various shapes, sizes, and materials, providing continuous and precise material supply for downstream assembly or processing equipment.

II. Characteristics and Limitations of Traditional Feeding Systems

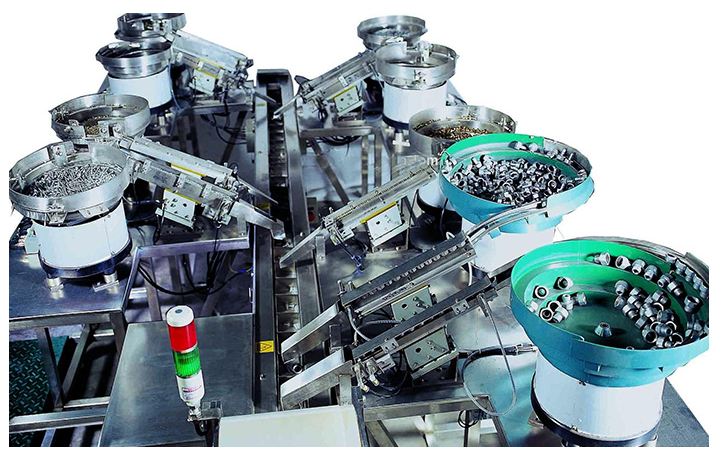

Traditional feeding systems are often single feeding solutions based on vibration plates, hoppers, or customized tracks. Such systems are typically designed for specific components:

Strong specificity: Feeding tracks or vibration plates are mostly single-shape and single-size, sensitive to part variations.

High changeover costs: Changing parts of different specifications requires replacing hardware molds or adjusting structures, resulting in long production line downtime.

Prone to material jamming or wear: Complex-shaped components are more likely to get stuck or worn in traditional feeding environments, affecting stability and lifespan.

Limited automation level: Most systems still require manual intervention for adjustment or maintenance, which is not conducive to unmanned production.

These limitations make traditional systems increasingly unable to meet modern manufacturing needs when facing small-batch, multi-variety, or high-precision processing.

III. Comparison Table: Flexible Feeding System vs Traditional Feeding System

| Comparison Dimension | Traditional Feeding System | Flexible Feeding System |

|---|

| Part Type Handling | Limited to single type | Multi-type universal |

| Changeover Difficulty | High | Low |

| Automation Level | Medium or low | High |

| Production Stability | Significantly affected by manual intervention | High-precision automatic execution |

| Maintenance & Operation Cost | Increases over time | Generally lower overall |

| Robot Integration | Requires custom docking | Native compatibility |

| Future Demand Adaptability | Weak | Strong |

IV. Danikor's Flexible Feeding Advantages

As an enterprise focused on industrial automation and production assembly solutions, Danikor concentrates on the innovation and service of intelligent and flexible feeding systems. Our flexible feeding system features high compatibility, quick changeover, low maintenance, and easy integration, capable of meeting complex assembly needs in new energy, automotive, 3C electronics, communications, and energy storage industries, providing more efficient and intelligent feeding capabilities for your production lines.

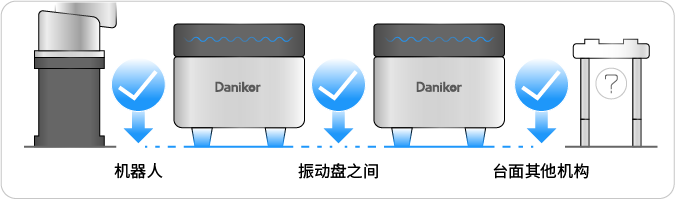

In recent years, Danikor has continuously optimized its product performance through technological innovation. For example, its vibration isolation function can isolate 95% of vibration energy from the workbench surface; the one-click calibration function optimizes operation procedures and corresponding algorithm matching, achieving one-click calibration for target materials, greatly reducing the workload of vision and robotic arm coordination. A reliable brand typically incorporates the latest technologies into its products to ensure they can meet constantly evolving market demands.

V. Conclusion

Against the backdrop of accelerated digital transformation in today's manufacturing industry, feeding systems are no longer just mechanical equipment that "gets materials to the right place," but a critical link affecting production efficiency, quality control, and expansion capabilities. Compared with traditional feeding systems, flexible feeding systems can provide higher automation levels, lower operating costs, and stronger production adaptability, making them an important choice for manufacturing enterprises implementing production line upgrades and intelligent transformation.

If you are seeking solutions to improve production efficiency, reduce manual dependency, and support diversified assembly production strategies, flexible feeding systems are undoubtedly a more competitive choice.